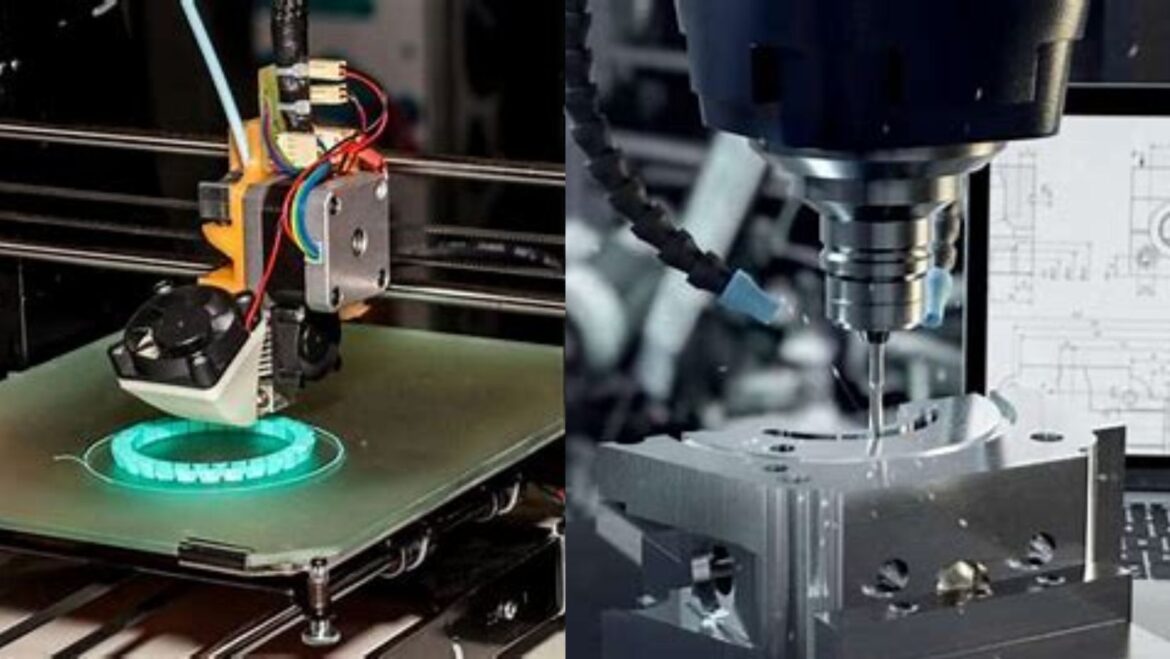

A very helpful tool for developing and creating innovative items in a range of materials is rapid prototyping manufacturing. The process allows us to incorporate feedback more quickly and efficiently, allowing us to iterate more often until we have generated the best possible product. Rapid prototyping also saves both time and money by producing working models faster than ever before.

Nonetheless, it’s critical to comprehend which material will work best for a precision rapid prototype as well as the many applications that might be made with them. In this article, we will examine some of the materials utilized most frequently in creating quick prototypes and what can be their applications. Let’s dig into the details!

Materials to Use for Rapid Prototyping

Following are some of the materials that can be used for the process of rapid prototype manufacturing:

Nylon (PA)

One of the materials that are most frequently employed in the production of quick prototypes is nylon. It is perfect for a range of applications, including automobile components, medical equipment, and consumer electronics, since it is strong, flexible, and long-lasting. Nylon is a fantastic material for 3D printing since it is also reasonably simple to deal with in comparison to other materials.

Polyvinyl Chloride (PVC)

Polyvinyl chloride (PVC) is another popular material for rapid prototyping applications due to its low cost and ease of fabrication. PVC offers excellent chemical resistance and rigidity, making it well-suited for products that will come into contact with harsh environments or require structural integrity under load-bearing conditions. PVC also has good weather ability properties so it can stand up to extreme temperatures without breaking down or becoming brittle over time.

Polyethylene (PET)

Polyethylene is another popular material used in rapid prototyping manufacturing due to its strength and flexibility. It has excellent thermal properties, making it suitable for applications where heat resistance is required. Polyethylene is often used to create prototypes or components that need to have good performance in extreme conditions such as high temperatures or high pressures.

POM (Delrin)

POM (also known as Delrin) is a type of polyoxymethylene plastic that has excellent mechanical properties such as wear resistance, low friction coefficient, dimensional stability, and heat resistance up to 100 degrees Celsius. POM is often used in automotive parts or robotics due to its ability to withstand extreme conditions without losing its shape or strength.

Acrylic (PMMA)

Acrylic, also called PMMA, is an acrylic plastic that offers excellent optical clarity and light transmittance. It has good impact resistance and hardness, making it an ideal choice for rapid prototyping applications. Acrylic is often used to create complex shapes because of its ability to be easily machined or molded into different forms. Additionally, acrylic can be painted or printed on with specialized inkjet printers to achieve unique looks and textures.

Conclusion

Rapid prototyping manufacturing makes it possible to quickly produce parts from a variety of different materials depending on the application requirements. The most common materials used include nylon, polyethylene, POM (Delrin), and acrylic. Each material offers unique advantages depending on the application including strength, durability, heat resistance, chemical resistance, and more. By understanding what type of material will best suit your requirements you can ensure that your prototype meets your expectations before going into full production mode!