Forged aluminum is a high-strength, lightweight material celebrated for its remarkable mechanical properties and wide extent of industrial applications. The producing handle, which involves heating aluminum to a flexible temperature and then forming it utilizing compressive powers, essentially refines its grain structure. This comes about in improved quality, strength, and reliability compared to other manufacturing strategies like casting or machining.

Forged aluminum’s prevalent strength-to-weight proportion, made strides in tensile quality, and resistance to affect and weariness make it perfect for basic components in aviation, car, and industrial apparatus. Its refined grain structure also contributes to way better erosion resistance, what is forged aluminum, guaranteeing life span and execution in requesting situations.

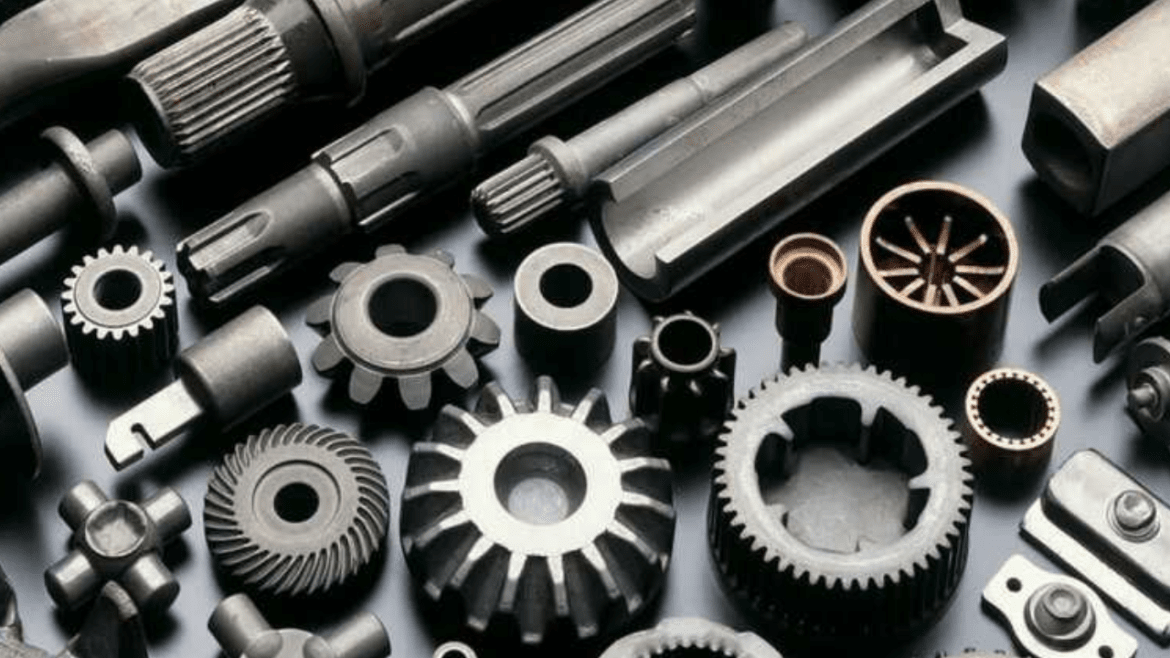

The Benefits and Applications of Forged Aluminum

Manufactured aluminum offers prevalent strength-to-weight proportion, improved mechanical properties, and excellent erosion resistance. These benefits make it perfect for aviation, car, military, mechanical apparatus, and high-end buyer goods. Its strength and consistency guarantee solid execution in requesting applications, making it an important fabric for different businesses.

Strength-to-Weight Proportion

Forged aluminum stands out due to its surprising strength-to-weight proportion, making it perfect for applications requiring lightweight but solid materials. This is often especially significant in the aerospace and car industries, where weight reduction is essential without compromising quality. Forged aluminum components can be lighter than steel partners while maintaining comparable or superior quality.

Mechanical Properties

The forging handle upgrades aluminum’s mechanical properties by aligning its inside grain structure. This comes about in higher tensile quality, improved affect resistance, and more noteworthy weariness resistance, making forged aluminum reasonable for components uncovered to high stretch and energetic loads.

Erosion Resistance

Aluminum shapes a defensive oxide layer when exposed to discuss, giving characteristic erosion resistance. The forging preparation improves this property by refining the grain structure, decreasing porosity, and minimizing surface blemishes that may lead to erosion.

Uniformity and Consistency

Forging guarantees a uniform and thick material structure, minimizing inner defects and irregularities. This basic integrity contributes to the unwavering quality and life span of manufactured aluminum components, decreasing the hazard of untimely disappointment.

Aviation

Within the aviation industry, forged aluminum is utilized for basic components such as aircraft basic parts, landing adapt, and motor components. Its quality, delicacy, and erosion resistance upgrade airplane execution, fuel proficiency, and toughness.

Automotive

The car segment uses forged aluminum in suspension parts, wheels, motor pieces, and transmission components. Its lightweight nature progresses fuel productivity, taking care of, and in general vehicle execution whereas assembly rigid security and toughness prerequisites.

Defense and Military

Forged aluminum’s quality and strength make it appropriate for military applications, including armored vehicles, weapon systems, and aviation defense gear. Its capacity to resist ballistic impacts and unforgiving natural conditions upgrades the reliability and operational viability of military equipment.

Mechanical Machinery

Forged aluminum is utilized in mechanical machinery and gear requiring lightweight components with tall quality and durability. Applications incorporate pressure-driven systems, mechanical tools, and overwhelming apparatus components.

Buyer Products

Beyond industrial and aviation applications, forged aluminum is esteemed in buyer products such as high-end bicycles, donning hardware, and outdoor equipment, where lightweight and strong materials are fundamental.

Conclusion

Forged aluminum’s interesting combination of quality, softness, and solidness positions it as a favored material choice in businesses that request high performance and reliability. The forging handle upgrades aluminum’s mechanical properties, making it competent to withstand extraordinary conditions while maintaining a lightweight profile. Its applications span basic segments like aviation, car, defense, and mechanical apparatus, where decreasing weight without compromising execution is fundamental. As innovation propels and businesses evolve, manufactured aluminum proceeds to play a significant part in forming long-term lightweight, high-strength materials over differing applications.