CNC turning machines make use of computer-managed precision to rotate a workpiece even as slicing equipment disposes of material, shaping it into cylindrical parts with high accuracy and consistency. These machines are vital in industries requiring particular parts including automotive, aerospace, medical devices, and electronics.

Employing automating the machining process, cnc turning machine ensures efficient manufacturing, minimum mistakes, and the capacity to handle an expansion of substances which includes metals, plastics, and composites. This era helps complex geometries, tight tolerances, and repeatable consequences, making CNC turning important for contemporary production worrying reliability and precision.

Applications of CNC Turning Machines

CNC (Computed Numerical Control) turning machines play a vital role throughout numerous industries by enabling the specific and efficient manufacturing of a wide variety of components. Right here are some applications of CNC turning machines throughout exclusive sectors:

Automotive Industry

Within the automobile industry, CNC turning machines are extensively used for manufacturing important additives that require excessive precision and reliability. CNC turning machines that produce shafts and axles with unique dimensions and surface finishes, vital for transmitting electricity and torque in engines and drivetrains. Diverse engine components consisting of pistons, cylinders, and camshafts are fabricated using CNC turning to satisfy stringent tolerances and performance necessities.

Aerospace Industry

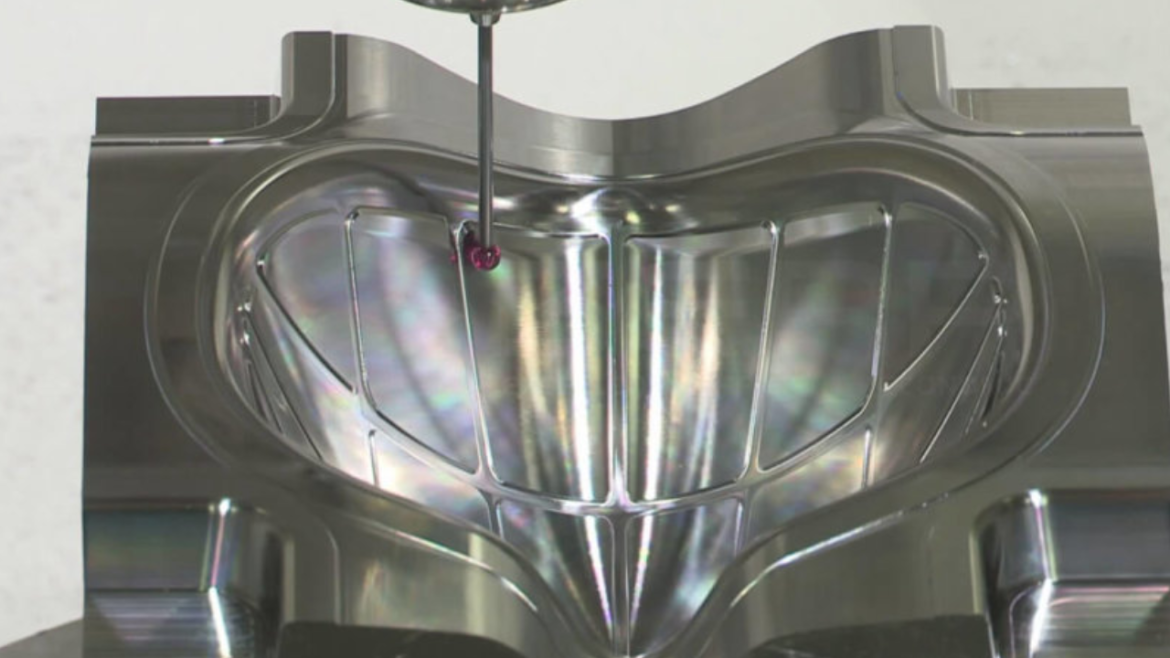

The aerospace sector relies on CNC turning machines for producing complex and excessive-overall performance components which are crucial for plane operations. CNC turning is used to fabricate turbine blades, shafts, and housings with complex geometries and substances which include titanium and nickel alloys. CNC turning machines are employed for generating structural additives like touchdown gear parts and wing assemblies with specific shapes and durability.

Medical Devices and Healthcare

CNC turning performs a crucial function in the scientific enterprise by utilizing elaborate and sterile additives used in various scientific gadgets. CNC turning machines fabricate surgical equipment and contraptions with unique dimensions and ergonomic designs, ensuring functionality and protection in the course of medical approaches. Parts for prosthetic limbs and implants are machined with the usage of CNC turning to satisfy affected person-specific necessities and biomedical standards. Parts for diagnostic machines and scientific imaging gadgets are manufactured with CNC turning to acquire high accuracy and reliability in healthcare diagnostics.

Electronics and Telecommunications

In the electronics industry, CNC turning machines are applied to produce additives that assist the functionality and reliability of electronic devices and telecommunications structures. CNC turning machines fabricate connectors, housings, and enclosures with precise dimensions and threaded capabilities for relaxed electric connections. CNC turning is used for the production of waveguide additives that facilitate the transmission of electromagnetic waves in telecommunications and radar structures.

Energy Sector

CNC turning machines play a crucial role within the energy enterprise by way of producing additives used in strength generation, renewable electricity, and oil and gas exploration. CNC turning is used for production additives along with turbine shafts, generator components, and steam valve components with excessive durability and precision. CNC turning machines produce valves, fittings, and drilling device components that withstand harsh working situations in oil and fuel exploration and manufacturing.

Manufacturing and Industrial Equipment

CNC turning machines are vital in general production and commercial sectors for producing an extensive range of components that aid manufacturing methods and equipment. CNC turning machines manufacture components like spindles, gears, and ball screws utilized in system gear and automatic manufacturing structures. CNC turning is used for generating precision components which include hydraulic cylinders, pistons, and fittings that ensure efficient operation of hydraulic and pneumatic structures.

Ending Thoughts

CNC turning machines reveal their versatility and importance throughout diverse industries by allowing the production of particular, complicated, and high-performance additives. From automobile and aerospace to clinical gadgets, electronics, power, and fashionable production, CNC turning plays a vital function in improving product satisfaction, operational performance, and technological advancement. As industries continue to adapt, CNC turning stays a cornerstone era driving innovation and competitiveness in worldwide markets.